J

John McIlroy

Guest

It’s fairly common knowledge that Skoda has made great progress by using a VW Group set of parts called MQB. These components (not only the chassis, but also key elements such as the transmissions and electronics) have underpinned a great swathe of the Skoda range, including the Kamiq, Karoq, Kodiaq and Octavia, over the past decade.

For Enyaq, though, Skoda has switched to a new all-electric toybox. It’s called MEB, which stands for Modularer E-Antriebs-Baukasten in German, if you’re asking. This is basically the all-electric equivalent of MQB. It’s already supporting some VWs, and upcoming models from Audi and Cupra will also use it. But the Enyaq will be the first European-built car from the family to be made outside Germany, at Skoda’s hometown factory in Mlada Boleslav in the Czech Republic.

The new set-up is designed to harness the knowledge gleaned from a decade of combustion-engined cars on MQB, while also maximising the benefits that can come from an architecture designed with purely electric powertrains in mind.

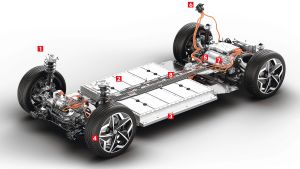

Here we break down the Enyaq’s bare MEB components, and for all the cutting-edge tech involved, the absence of a combustion engine means that there are actually fewer parts than you might expect. Through sophistication, it seems, comes simplicity.

This is possibly where MEB comes closest to its MQB relative. The front configuration is a MacPherson strut layout, and the same arrangement appears on everything from the Audi A3 to the Skoda Octavia.

But MEB is actually a rear-wheel-drive chassis, and there wouldn’t be room for the electric motor and transmission at the back if a simple torsion beam were fitted. So all Enyaqs feature a more complex multi-link layout instead.

The battery packs on MEB are made up of certain numbers of modules, each of them comprising 24 lithium-ion cells. The smallest configuration, which isn’t offered on the Enyaq, has seven modules, but the set-up in this image is a medium spec, including nine modules stretched across 10 14cm-thick compartments.

The remaining area is occupied by the battery’s control unit. When the MEB is fitted with its largest 77kWh battery pack, as in an Enyaq iV 80, it has six compartments on each side, all of them filled with modules, and the control interface gets an additional ‘half-width’ compartment that stretches right across the vehicle.

Any battery pack is a hefty component in the vehicle – heavier than a combustion engine, and almost half a tonne if it’s the biggest-capacity unit in the Enyaq iV 80. So it makes sense to mount it as low down in the chassis as possible, and in the centre of the vehicle.

In MEB, the battery pack is covered by an aluminium case and frame that help the Enyaq’s torsional rigidity by being bolted to the chassis; this also protects the battery in an accident.

Electric vehicles make use of every bit of energy available, and that includes harnessing energy that would otherwise be lost during braking. This recuperation does some of the heavy lifting when you press the left-hand pedal and, as a result, there’s less need for massive conventional stopping power.

The Enyaq has disc brakes at the front, with a twin-calliper arrangement on the big-battery iV 80 model, but relatively simple drum brakes at the rear.

A car the size of the Enyaq would probably be powered by at least a 1.5-litre petrol engine. But in single-motor form, it has an electric motor so small that you could fit it inside a sports bag. It weighs just 90kg, helping to offset a little of the extra mass brought by the battery pack.

The platform is rear-wheel drive as standard – as shown above – but an additional, smaller e-motor can be fitted to the front axle to deliver four-wheel drive. Skoda will use this layout on the Enyaq 80x and a forthcoming vRS version.

The motors don’t need quite so much thermal management as a combustion engine, but they do produce some heat; this is dealt with by a conventional radiator at the front, and an electric pump that circulates the cooling fluid.

MEB supports AC and DC charging via a Type 2 interface, the most common kind of electric-car plug. For home charging you’ll only use the upper section of the socket; if you need to charge up in a hurry while away from home, a DC connection will make use of an additional two pins at the bottom of the plug.

MEB allows car makers to decide the maximum DC charging rates; in the case of the Enyaq, the fastest 125kW setting is reserved for the 80 and 80x, plus the vRS model.

The Enyaq’s motors can spin at up to 16,000rpm, so a gearbox is required to help slow this down for transmission to the wheels. The single-speed unit is small enough to be integrated into the motor. And it doesn’t have a reverse gear; the electric motor just flips its propulsion to send the car the opposite way.

With no complex gearbox or propshaft like on a combustion engined-vehicle, there’s no need for a conventional transmission tunnel. This slim ‘spine’ down the centre of MEB is used for cabling, both for electricity needed by the motor(s) and also for data being fired about by the battery control systems.

Continue reading...

For Enyaq, though, Skoda has switched to a new all-electric toybox. It’s called MEB, which stands for Modularer E-Antriebs-Baukasten in German, if you’re asking. This is basically the all-electric equivalent of MQB. It’s already supporting some VWs, and upcoming models from Audi and Cupra will also use it. But the Enyaq will be the first European-built car from the family to be made outside Germany, at Skoda’s hometown factory in Mlada Boleslav in the Czech Republic.

- SEE MORE New Skoda Enyaq iV 2021 review

The new set-up is designed to harness the knowledge gleaned from a decade of combustion-engined cars on MQB, while also maximising the benefits that can come from an architecture designed with purely electric powertrains in mind.

Here we break down the Enyaq’s bare MEB components, and for all the cutting-edge tech involved, the absence of a combustion engine means that there are actually fewer parts than you might expect. Through sophistication, it seems, comes simplicity.

1. Suspension

This is possibly where MEB comes closest to its MQB relative. The front configuration is a MacPherson strut layout, and the same arrangement appears on everything from the Audi A3 to the Skoda Octavia.

But MEB is actually a rear-wheel-drive chassis, and there wouldn’t be room for the electric motor and transmission at the back if a simple torsion beam were fitted. So all Enyaqs feature a more complex multi-link layout instead.

2. Battery pack

The battery packs on MEB are made up of certain numbers of modules, each of them comprising 24 lithium-ion cells. The smallest configuration, which isn’t offered on the Enyaq, has seven modules, but the set-up in this image is a medium spec, including nine modules stretched across 10 14cm-thick compartments.

The remaining area is occupied by the battery’s control unit. When the MEB is fitted with its largest 77kWh battery pack, as in an Enyaq iV 80, it has six compartments on each side, all of them filled with modules, and the control interface gets an additional ‘half-width’ compartment that stretches right across the vehicle.

3. Battery frame

Any battery pack is a hefty component in the vehicle – heavier than a combustion engine, and almost half a tonne if it’s the biggest-capacity unit in the Enyaq iV 80. So it makes sense to mount it as low down in the chassis as possible, and in the centre of the vehicle.

In MEB, the battery pack is covered by an aluminium case and frame that help the Enyaq’s torsional rigidity by being bolted to the chassis; this also protects the battery in an accident.

4. Brakes

Electric vehicles make use of every bit of energy available, and that includes harnessing energy that would otherwise be lost during braking. This recuperation does some of the heavy lifting when you press the left-hand pedal and, as a result, there’s less need for massive conventional stopping power.

The Enyaq has disc brakes at the front, with a twin-calliper arrangement on the big-battery iV 80 model, but relatively simple drum brakes at the rear.

5. Electric motor

A car the size of the Enyaq would probably be powered by at least a 1.5-litre petrol engine. But in single-motor form, it has an electric motor so small that you could fit it inside a sports bag. It weighs just 90kg, helping to offset a little of the extra mass brought by the battery pack.

The platform is rear-wheel drive as standard – as shown above – but an additional, smaller e-motor can be fitted to the front axle to deliver four-wheel drive. Skoda will use this layout on the Enyaq 80x and a forthcoming vRS version.

The motors don’t need quite so much thermal management as a combustion engine, but they do produce some heat; this is dealt with by a conventional radiator at the front, and an electric pump that circulates the cooling fluid.

6. Charging

MEB supports AC and DC charging via a Type 2 interface, the most common kind of electric-car plug. For home charging you’ll only use the upper section of the socket; if you need to charge up in a hurry while away from home, a DC connection will make use of an additional two pins at the bottom of the plug.

MEB allows car makers to decide the maximum DC charging rates; in the case of the Enyaq, the fastest 125kW setting is reserved for the 80 and 80x, plus the vRS model.

7. Gearbox

The Enyaq’s motors can spin at up to 16,000rpm, so a gearbox is required to help slow this down for transmission to the wheels. The single-speed unit is small enough to be integrated into the motor. And it doesn’t have a reverse gear; the electric motor just flips its propulsion to send the car the opposite way.

8. Transmission tunnel

With no complex gearbox or propshaft like on a combustion engined-vehicle, there’s no need for a conventional transmission tunnel. This slim ‘spine’ down the centre of MEB is used for cabling, both for electricity needed by the motor(s) and also for data being fired about by the battery control systems.

Continue reading...